A new year, and a renewed commitment to more sustainable and environmentally friendly practices. Over the past few years, we have made a more conscious effort to put reducing our environmental impact at the forefront of our operations, and this year is no different. During 2023 we look forward to seeing the expansion of our solar energy installation at our Whittlesey site, an increase in the capabilities of our in-house recycling facility, and the launch of our impressive new Temple chair – our first recyclable chair made from 90% recycled plastic.

Solar Panels

RGE has made significant capital investment in the expansion of our solar energy installation at our Whittlesey site. The project builds upon the existing 250kwh system, installed in 2018, and when completed will mean that the installed solar panels will be just under a 1MWh system. This means that on a sunny, summer’s day the operation at Whittlesey can be powered almost entirely by the sun. Our factory at Whittlesey also makes use of our Thingtrax IT system, which allows us to schedule which machines will run each day in order to use the least amount of energy whilst providing the highest and most efficient levels of production. We look forward to sharing updates from the installation of our new solar panels early this year.

The Regrind Centre

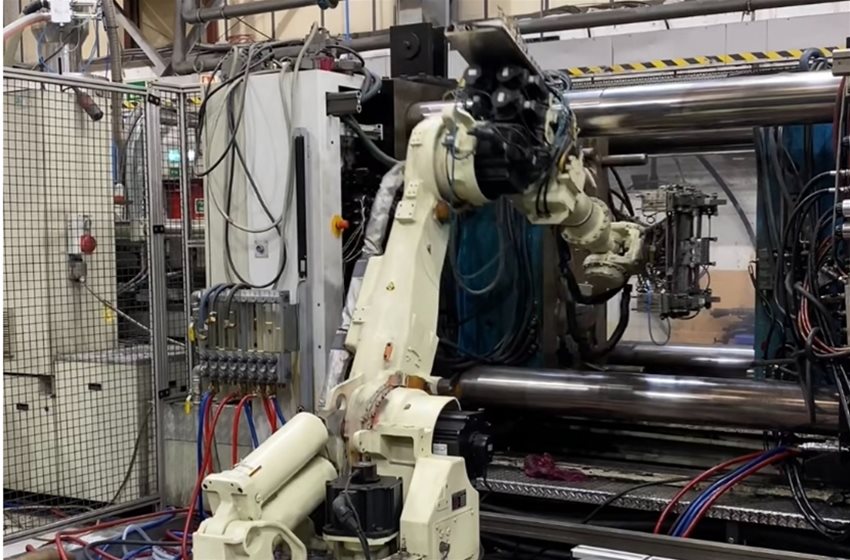

Ever since RGE began moulding in the 1970s, recycling has been at the heart of our operation. Regrinding the cold runner, or sprue, on many jobs was typical when utilising a machine-side sprue grinder, and often this regrind material was dosed back into the melt to be completely circular. On top of internal recycling of raw material, RGE also has a number of large regrind machines, giving our operations capability of recycling more 20 tonnes of raw material per day.

Following the launch of our in-house recycling facility in 2021, the Regrind Centre, RGE are now beginning to offer a buy back service, processing any extra stock or old products to be recycled back into material which can be reused in the production of new product or goods parts. The centre is capable of processing PP, ABS, PA, TPE, and PBT + PET, and will be expanding to grind other plastics as they become available.

Recently, RGE has been making recycled polymer grades of our own to use in new products. This operation is run under the company banner of Regen Plastics and has experienced significant investment over the last 3 years. The grades now available are Recycled PP, Recycled Glass Filled PP and Recycled Glass Filled Nylon. All of these grades are made using outside material inputs.

RGE is extremely proud of being part of the circular economy of recycling and production of new products designed to used recycled material in their creation.

Recycled Products and the Temple

The recycled material produced at our Regrind Centre is then reused to create our range of recycled products. Our multiuse MultiNest crates, for example, can be made from recycled polypropylene, and are available to buy in recycled black. MultiNest crates, Pallet Collars and Universal Display Pallets make up our current range of material handling products produced from recycled plastics. This provides a more environmentally conscious alternative to using virgin plastic equivalents, at a cheaper price. Our recycled products are long lasting and still retain a comparable durability and strength of our virgin polypropylene products. While robust and designed for a long and useful life, our products made from recycled material can still be recycled again.

This year, we are also excited to launch our first recyclable chair made from recycled materials – the Temple. Made from approximately 90% recycled plastic using injection moulding, there is little-to-no waste throughout the entire production process. With sustainability at the core of its design, the Temple can be refurbished as needed and eventually recycled at the end of its life.

Find out more or enquire here.

Please contact us if you have a product idea that we can manufacture using a sustainable recycled material in our sun-powered, local factory enquiry@rgegroup.com